PEEK is a breakthrough for medical devices

PEEK medical devices have been on the market for a couple decades, and they are already a frontline option in some of the most demanding medical applications. These applications require components that are biocompatible and adaptable, and PEEK offers both. PEEK is in demand among medical facilities and their surgical teams, and it’s quickly being adopted by additional fields of medicine.

What medical devices feature PEEK?

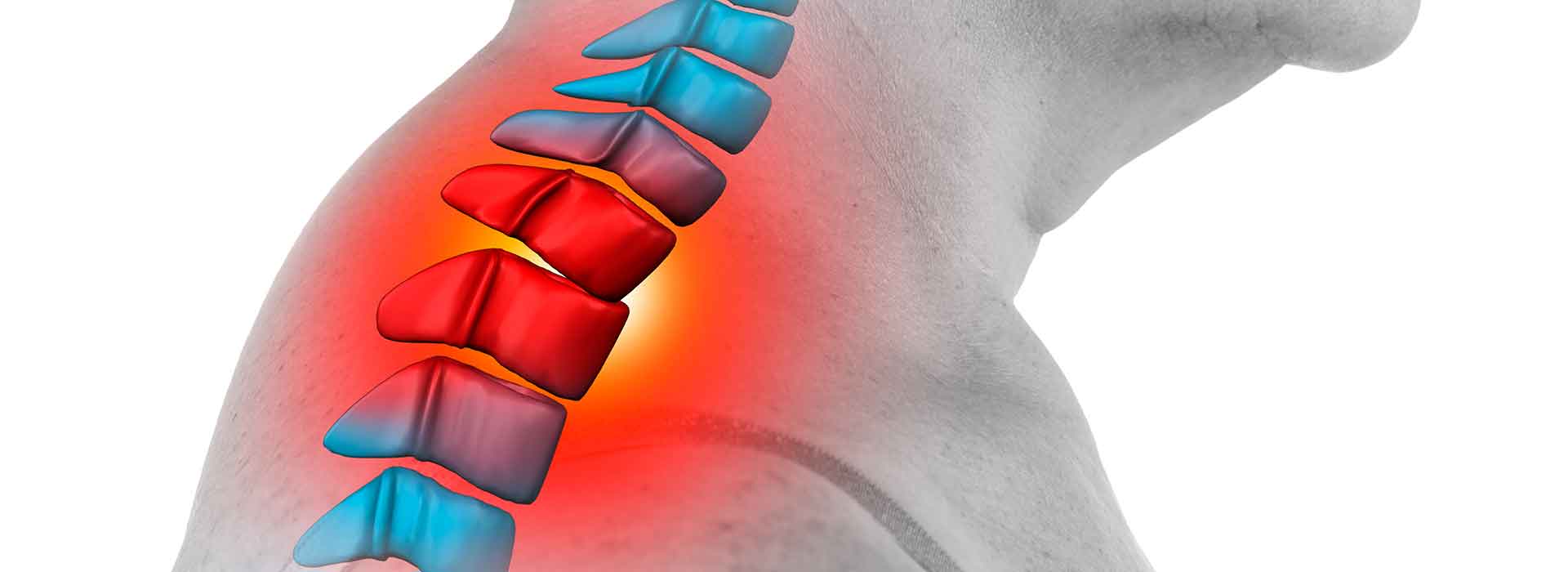

Almost all PEEK devices and components are implanted, and though PEEK components are found in many medical disciplines, most of them are used for spinal surgeries, trauma fixation and orthopedic procedures. The first PEEK devices put in widespread use were intervertebral fusion cages, and the first were introduced to the market in the late 90s. In the 20 years since, PEEK spinal implants have earned their place as the frontline option for many spine and vertebra disorders, including degenerative disc disease, spinal stenosis, degenerative scoliosis and degenerative spondylolisthesis.While PEEK is still most often utilized as a spinal implant, the material has been developed for many more medical applications, including:

- Trauma fixation – PEEK is considered a primary biomaterial of the future in trauma fixation procedures, for several reasons. PEEK is regularly fabricated into bone plates, nails, anchors and screws.

- Orthopedic – PEEK is also a potential replacement for metal in orthopedic procedures, and particularly knee and hip arthroplasty. Further, PEEK can be used in both partial and total joint replacement applications, and researchers are looking into the polymer’s potential in other joint replacement procedures.

- Dental – PEEK is a prized biomaterial for dentists, and is most often incorporated into removable partial dentures. PEEK is a perfect fit for the oral cavity and performs better than metal components across the board.

- Cardiovascular – PEEK has only been used for cardiovascular applications for a short time, but its potential in this area has also been noted. Currently, PEEK is a vital part of the Less Invasive Ventricular Enhancement, or LIVE, treatment. LIVE is a safer alternative to other ventricular restoration procedures, and is usually needed to repair damage to the heart following a myocardial infarction. PEEK’s role in the LIVE procedure is to act as an anchor tether, keeping a pair of ventricle-stabilizing anchors in place.

These are the primary PEEK medical device applications, but this is only a partial list. PEEK components can also be found in prosthetics, surgical instruments and laboratory equipment.

Why is PEEK a good fit for medical devices?

With so many current and potential applications for PEEK in medicine, it’s clear that the polymer is uniquely well suited to the industry. What traits, then, does PEEK offer that make it such a natural fit?

- A modulus that closely resembles bone – PEEK’s defining characteristic is its modulus, which is as close to cortical bone as can be found among biomaterials. It was PEEK’s modulus that first garnered attention among medical device manufacturers, and its advantage in this area has only strengthened as PEEK has been developed further. Ideally, an implant would behave like the body’s own tissues. This is particularly true when an implant must replace bone because if the modulus is off, neighboring bone may suffer mineral loss. This is the primary concern with implants made from titanium, as titanium is much stiffer than bone and bears more weight than it should. The additional weight bearing means nearby bone isn’t stimulated properly, and poorly stimulated bone eventually suffers from resorption. The complications resulting from this resorption aren’t immediately felt, but bone mineral loss can increase the likelihood of osteoporosis or fractures. None of this is theory, as the impact of titanium implants on bone mineral density have been studied extensively. One of those studies, published in the European Spine Journal, found that titanium implants can cause bone subsidence (or caving in) rates of around 20 percent. Subsidence rates arising from PEEK implants are much lower and frequently remain under the 10 percent mark.

- Radiolucency during most imaging – If PEEK’s modulus is the top reason why medical facilities choose the polymer, then PEEK’s radiolucency is a close second. This radiolucent quality is inherent to unfilled PEEK, and provides excellent transparency on X-rays, CT and MRI images. Radiolucency is of major concern during spinal implant procedures. When a surgeon operates around the spine, they must do so with pinpoint precision, and it’s easier to be precise when surgeons can see exactly where the implant is and how it is affecting nearby tissues. PEEK’s radiolucency ensures there are no imaging artifacts that will interfere with monitoring efforts. There are applications, though, where unmodified PEEK may be too transparent. Fortunately, PEEK can be augmented with additives like barium sulfate to generate image contrast.

- Ability to be modified – PEEK’s modulus can be modified to a great extent for applications that require additional rigidity and mechanical strength. This is done using Carbon Fibers, integrated into the PEEK during processing. In addition to enhanced stiffness, carbon-reinforced PEEK also provides superior creep strength. PEEK’s modifiable modulus is also a valuable trait for trauma fixation procedures, as additional fatigue strength and resistance is also impressive, and some varieties of PEEK are much more resilient in this regard, compared to metal components.

PEEK medical devices and components are already in extensive use in many fields, and it’s only been 20 years since PEEK was first adopted for medical use. No other biomaterial has achieved so much in such a short amount of time, and PEEK devices are set to achieve even more in the near future.