How can PEEK and Torlon enhance the capabilities of prosthetics?

In the U.S., more than two million people are living without one or more of their limbs. That number is only going to increase as the population grows older, and some projections have that number doubling by 2050. Close to 200,000 people undergo amputations, which are often the result of complications from other medical conditions, like diabetes and vascular disease. Coping with limb loss is far from automatic, as about 30 percent of people living without a limb suffer from frequent depressive episodes. Clearly, there is a need for better prosthetics.

Fortunately, that is exactly what is expected in the near future. Already, prostheses can closely mimic the appearance of a limb, and the most advanced prosthetics can reasonably match natural function as well. As prostheses continue to improve, fine motor control and subtle limb movements will be possible.

Prosthetic devices are sorted into several categories, depending on what part of the limb they are designed to replace, and the degree of functionality they provide to the patient.

Polymer Prosthetic Applications

Upper extremity prostheses are designed to replace the arm or hand, in part or in total. These can be further defined as shoulder disarticulation, transhumeral, elbow disarticulation, transradial, wrist disarticulation and forequarter. Total and partial hand amputation, as well as total and partial finger amputation procedures are common forms of limb removal, and a variety of prostheses can be developed to mitigate hand or finger loss.

Upper extremity prostheses can also be subcategorized into passive, body powered and externally powered.

- Passive prostheses – Passive prostheses are static or adjustable prostheses, but they provide either very little articulation, or none at all. They are intended for a cosmetic purpose or for a particular functional purpose. Passive prostheses may not provide grasping capabilities.

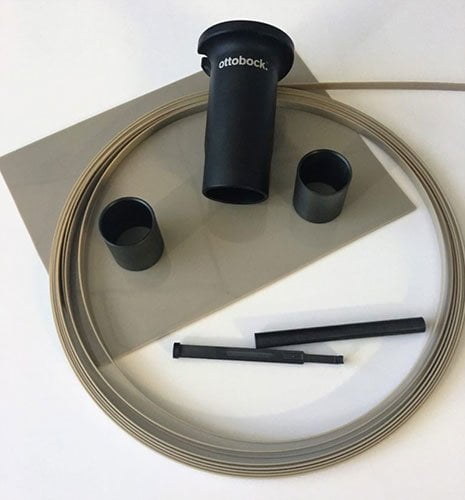

- Body powered prostheses – Body powered prostheses, also referred to as cable operated limbs, provide additional articulation and functional capabilities. A body powered prosthesis operates using mechanical energy provided by the body, delivered through one or more cables.

- Externally powered prostheses – Externally powered prostheses are at the frontier of prosthetics research in that they link what remains of the original limb with an electrode interface. When muscles are engaged in the upper arm, the electrodes sense the engagement and respond by opening or closing the prosthetic hand.

Lower extremity prostheses are designed to replace the leg or foot, in part or in total. These can be further defined as transtibial, transfemoral, knee disarticulation and hip disarticulation.

Total or partial foot amputation, as well as toe amputation are frequently seen in limb removal cases.

Most lower extremity prostheses are either transfemoral, which replaces a leg missing above the knee, and transtibial, which replaces a leg missing below the knee. Transfemoral amputees, in particular, have difficulty adjusting to locomotive challenges imposed on them by their condition. As such, they require a prosthesis that is designed for comfort and control. PEEK and Torlon are essential materials in prosthesis design and production. Many of the gains made in prosthesis technology are the result of improved materials, and high-performance polymers like PEEK and Torlon are a clear example of this. PEEK and Torlon in the form of bushings, spacers and seals, enhance the durability and comfort of modern prostheses. How do they do this?

1. Excellent stiffness and strength

PEEK and Torlon are inherently strong and have a high modulus, so they provide superior load bearing ability.

2. Can be modified with fillers or additives

PEEK and Torlon can be readily modified with other materials to improve their already impressive properties. This includes enhanced wear resistance, so prosthesis components are strong and viable even after years of use.

3. Strong production tolerances

PEEK and Torlon components are fabricated using precise, easily repeatable processes, so they can be built with extremely tight tolerances.

Advanced prostheses demand advanced materials, and high-performance polymers like PEEK and Torlon are on the leading edge.